How Much Does Commercial Gas Boiler - Commercial Gas Boiler Price

2025-06-17 09:32:56Commercial Gas Boiler Prices: What You REALLY Need to Know

Looking into commercial gas boilers? You're probably wondering about cost. The average price for a new commercial gas boiler is between $5,000 and $25,000. The price depends on the size and model of the boiler. This article will explain their differences in detail and guide you in selecting the right boiler.

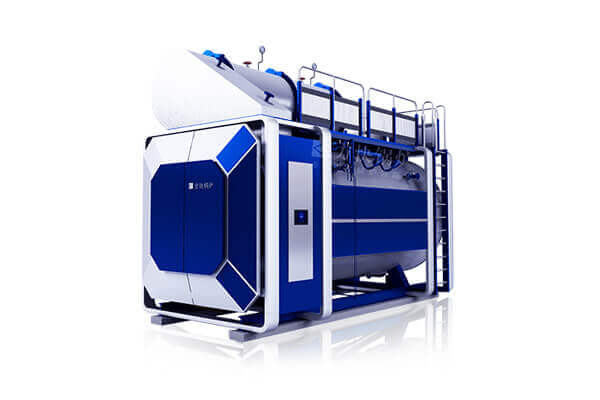

1. What Exactly is a Commercial Gas Boiler?

Think big. Unlike your home boiler, a commercial gas boiler heats large spaces: offices, factories, hotels, schools, apartment blocks. It uses natural gas or LPG to make lots of hot water or steam. Output is measured in kilowatts (kW) – often starting around 70kW and going way up. These units are built tough for heavy, often constant, use. They usually connect to building management systems too.

2. How Do They Work? (The Simple Version)

It's straightforward:

-

Gas burns inside a sealed chamber.

-

Hot gases flow through a heat exchanger (like pipes).

-

Water surrounds these pipes and gets hot.

-

Pumps move this hot water (or steam) to radiators, air handlers, or processes.

-

Cooled gases exit through a flue.

-

Smart controls adjust everything for efficiency and safety.

3. Main Types You'll See

Your choice affects commercial gas boiler prices and performance big time:

-

Fire-Tube Boilers: Hot gases go through tubes sitting in a water tank. Pros: Tough, simpler, often cheaper upfront. Good for lower pressure steam or lots of hot water. Cons: Bigger, heavier. Common in older setups.

-

Water-Tube Boilers: Water runs inside tubes heated by gases outside. Pros: More efficient, faster steam, handles high pressure, more compact for the power. Cons: Often higher initial cost. Preferred for big, modern buildings.

-

Modular Condensing Boilers (The Smart Choice Now): Several smaller boilers work together. Key feature: They "condense." This means they squeeze extra heat from the exhaust gases, making them super efficient (often over 90%). Modules turn on/off only as needed, saving fuel and providing backup if one fails. Highly recommended for most new installs or upgrades. The fuel savings usually justify the price.

-

Commercial Combi Boilers: Less common. Provide heating AND hot water instantly from one unit. Good for smaller places with steady hot water demand.

4. How Long Do They Last?

Treat them right, and a good commercial gas boiler should last 15 to 25 years. What shortens its life?

-

Poor Water Quality: Limescale and corrosion are killers. Water treatment is NOT optional.

-

Skipping Maintenance: Annual servicing is essential. Ignore it, pay dearly later.

-

Cheap Equipment: Better materials cost more upfront but last longer.

-

Constant Heavy Use: Like any machine, running flat-out wears it faster.

-

Bad Environment: Damp, dusty boiler rooms aren't ideal.

5. The Good and The Not-So-Good

Why Choose Gas?

-

High Efficiency (Especially Condensing): Modern condensing models turn over 90% of fuel into heat. That means lower bills and less CO2 than old boilers.

-

Lower Fuel Costs (Usually): Gas is often cheaper per unit than electricity or oil.

-

Proven & Reliable: It's a mature technology. Well-maintained boilers are workhorses.

-

Easy to Find Help: Gas engineers and parts are widely available.

-

Quick Response: They heat up fast when demand changes.

The Downsides:

-

Needs a Gas Line: No gas? No boiler. Installation needs access.

-

Flue & Ventilation Hassle: Requires proper exhaust piping and air supply. Adds complexity/cost.

-

Still Produces CO2: Cleaner than oil or coal, but not zero-carbon. Future regulations are a factor.

-

Maintenance is Key: You must service them yearly. No shortcuts.

-

Big Upfront Cost: Quality boilers and installation are significant investments.

-

Future Uncertainty: As we move away from fossil fuels, gas boilers might become less desirable long-term.

6. Gas vs. The Alternatives: A Quick Look

How does gas stack up? Let's compare:

-

vs. Oil Boilers:

-

Gas usually has lower, more stable fuel costs than oil.

-

Gas burns cleaner (less CO2, no smell).

-

Oil needs on-site storage tanks. Gas uses a pipeline.

-

Similar upfront and maintenance costs.

-

-

vs. Electric Boilers:

-

Electric boilers cost less to buy and install. Very simple.

-

BUT, electricity is often much more expensive per unit of heat than gas. Running costs can be sky-high.

-

Electric is 100% efficient at the boiler, but how the electricity is made matters for overall carbon footprint.

-

Very low maintenance.

-

-

vs. Biomass Boilers:

-

Biomass (wood pellets/chips) can be low-carbon (if sourced sustainably).

-

Fuel costs can be low but vary widely. Needs HUGE storage space.

-

Highest upfront cost. Complex installation. Highest maintenance (ash removal, cleaning).

-

Boilers are generally less efficient than modern gas condensing.

-

7. Decoding Commercial Gas Boiler Prices

So, what's the damage? Prices vary wildly: Anywhere from $5,000 to over $25,000+ USD. Why the huge range?

-

Size Rules Everything (Seriously, kW is Key): Look, a dinky 100kW unit for a corner shop? Pocket change next to a beastly 2000kW monster for a factory floor. Output = Cost. Simple as that. Type? Yeah, That Matters Too: Old-school fire-tube boiler? Cheaper upfront, sure. But that fancy modular condensing system? Pays you back month after month in gas savings. You do the math.

-

Efficiency Costs More... Then Pays You Back: Higher efficiency models sting upfront. But watching your gas bills plummet? That's the sweet spot. Payback period can be surprisingly short – sometimes just a few years.

-

Brand Names? You Pay For 'Em: Viessmann, Worcester Bosch Commercial, Remeha, Vaillant... these Euro brands cost more. Why? Better build. Fewer headaches. Smarter controls. Budget brands exist, but caveat emptor.

-

What's It Made Of? (Hint: Steel Matters): Stainless steel heat exchangers cost a premium over aluminium or basic steel. Worth it? Absolutely. They laugh at corrosion and last way longer. Don't cheap out here.

-

Modular Systems = More Cash, More Upside: Why pay more for several small boilers instead of one big one? Two words: Backup & Efficiency. One module dies? The others pick up the slack. Running partial load? They sip fuel, not guzzle it.

-

Smart money. Smart Controls = Smarter Price Tag: Want fancy building integration or remote tweaking from your phone? That'll cost ya. Cool? Yes. Necessary? Depends.

-

Installation: The Hidden Cost Monster: Forget the boiler sticker price for a sec. Where are you putting it? How long's the flue run? Gas line a nightmare? Hooking into ancient pipes? Labour costs brutal? Yeah, install can easily double your total cost. No joke.

-

The Extras Will Bite You: Pumps. Expansion tanks. Water treatment gizmos. Flue kits. Gas valves. It's death by a thousand cuts. Budget for the whole system, not just the shiny boiler box.

8. Maintenance: Don't Skip This!

Think you can dodge maintenance? Bad plan. Real bad. Skimping here jacks up your true cost big time. Here's how:

-

Fuel Bills Go Sky-High: Gunked-up heat exchangers work like dogs. Efficiency tanks. Your gas meter spins like a top. Cash burns.

-

Breakdowns = Nightmare Fuel: Something major blows? That's emergency call-out fees (cha-ching!), premium parts (ouch!), and maybe even lost business if the heat's off. Expensive panic.

-

Safety? You Playing With Fire: Faulty gas kit is no joke. Carbon monoxide leaks are silent killers. Enough said.

-

Early Grave for Your Boiler: Neglect it? That 20-year lifespan shrinks to 10. Now you're buying a whole new system way sooner. Brutal.

What Maintenance Actually Looks Like (No Fluff):

-

Annual Service: NON-NEGOTIABLE. A proper engineer does: Safety checks (gas pressure, exhaust, devices), burner clean, heat exchanger scrape-down. Costs: $250 - $650+ per module. Worth every penny.

-

Water Treatment: Your Boiler's Lifeline. Test the water. Dose the chemicals (inhibitors/conditioners). Stop scale & corrosion murdering your system. Budget for it. Flushes hurt, but are sometimes needed.

-

Wear & Tear Parts Die: Pumps croak. Valves stick. Sensors lie. Replace them before they fail catastrophically. Proactive = cheaper.

-

Flue Check: Is It Breathing? Make sure nothing's blocked or leaking. Basic, critical.

-

Paper Trail = Lifesaver: Log every service, every repair. Proves you cared. Helps the next tech fix stuff faster.

The Bottom Line: Price Tag Lies

Yeah, the upfront commercial gas boiler price is a gut punch. But the real cost? That's TCO – Total Cost of Ownership. Ignore it at your peril.

-

Fuel Bills: A top-tier condensing boiler saves you stacks monthly. That premium price? It pays rent in your wallet.

-

Reliability: Good gear + tight maintenance = Fewer 3 AM panic calls. Less downtime. More sleep.

-

Longevity: Treat it right, and a premium boiler lasts decades. Skip maintenance? Start saving for a replacement now.

-

Safety: Proper care keeps people alive.

Do your homework. Get quotes, sure, but ask about efficiency ratings, expected lifespan, maintenance costs, and local fuel prices. Get a proper heat load calculation done – an oversized or undersized boiler is a waste of money. Work with experienced HVAC professionals. Choosing the right commercial gas boiler is about value and peace of mind for years, not just the initial price tag.

Consultation

Consultation