Gas Boiler Heating System Prices 2025 | Cost Guide by Type & Size

2025-06-12 15:10:37As a homeowner considering a new heating system, understanding gas boiler prices is crucial for making an informed decision. This comprehensive guide will walk you through everything you need to know about gas boiler heating system costs, helping you budget properly and choose the best option for your home.

How Gas Boiler Heating Systems Work

Before diving into costs, let's first understand how these systems operate. A gas boiler heating system works by:

-

Burning natural gas or propane in a combustion chamber

-

Transferring the generated heat to water contained within the boiler

-

Circulating the heated water through pipes to radiators, baseboard heaters, or underfloor heating systems

-

Releasing heat into your living spaces

-

Returning cooled water back to the boiler to be reheated

This closed-loop system provides consistent, comfortable heat throughout your home. Unlike forced-air systems that blow dry air, hydronic heating maintains better humidity levels and doesn't distribute allergens.

Factors Affecting Gas Boiler Heating System Prices

Several key factors influence the final cost of your gas boiler heating system:

1. Boiler Type

-

Conventional boilers: $3,500-$7,000 installed

-

Combi boilers: $2,500-$6,000 installed

-

System boilers: $4,000-$8,000 installed

2. Efficiency Rating

-

Standard efficiency (80-85%): Lower upfront cost

-

High efficiency (90-98%): Higher initial price but lower operating costs

3. Home Size and Heating Needs

-

Small homes (under 1,500 sq ft): $2,500-$5,000

-

Medium homes (1,500-3,000 sq ft): $5,000-$8,000

-

Large homes (over 3,000 sq ft): $8,000-$15,000

4. Fuel Type

-

Natural gas: Most common and cost-effective

-

Propane: 20-30% more expensive but necessary where gas lines aren't available

5. Installation Complexity

-

Simple replacement: $1,500-$3,000 labor

-

Complete new system: $3,000-$6,000+ labor

Detailed Cost Breakdown by Boiler Type

Conventional Boiler Systems

Conventional (also called regular or traditional) boiler systems consist of:

-

A boiler unit

-

Hot water storage tank

-

Network of radiators or baseboard heaters

Average Costs:

-

Equipment: $1,500-$3,500

-

Installation: $2,000-$3,500

-

Total: $3,500-$7,000

Best for:

-

Larger homes with multiple bathrooms

-

Homes with existing radiator systems

-

Households with high simultaneous hot water demand

Combination (Combi) Boilers

Combi boilers provide both space heating and domestic hot water in one compact unit, eliminating the need for a separate water tank.

Average Costs:

-

Equipment: $1,500-$3,500

-

Installation: $1,000-$2,500

-

Total: $2,500-$6,000

Best for:

-

Small to medium-sized homes

-

Homes with limited space

-

Households with moderate hot water needs

System Boilers

System boilers incorporate key components like the expansion vessel and pump within the unit, making installation simpler than conventional systems.

Average Costs:

-

Equipment: $2,000-$4,500

-

Installation: $2,000-$3,500

-

Total: $4,000-$8,000

Best for:

-

Medium to large homes

-

Homes with good water pressure

-

Households wanting a balance of performance and efficiency

Additional Cost Considerations

Beyond the basic boiler and installation, several other factors can affect your total investment:

1. Radiators or Heating Emitters

-

New radiators: $200-$800 each

-

Baseboard heaters: $50-$200 per unit

-

Underfloor heating: $6-$15 per sq ft

2. System Upgrades and Modifications

-

New piping: $5-$15 per linear foot

-

Zone valves: $150-$300 per zone

-

Thermostats: $100-$300 each

3. Permits and Inspections

-

Building permits: $50-$300

-

Gas line inspection: $100-$250

4. Annual Maintenance Costs

-

Routine service: $150-$300 per year

-

System flush: $300-$600 every 5 years

Energy Efficiency and Long-Term Savings

While high-efficiency models cost more upfront, they can save significantly on operating costs:

| Efficiency Rating | Annual Fuel Cost (avg. 2,000 sq ft home) | Payback Period |

|---|---|---|

| 80-85% (standard) | $900-$1,100 | N/A |

| 90-95% (high) | $700-$900 | 4-7 years |

| 96-98% (premium) | $600-$800 | 6-9 years |

Key efficiency features to look for:

-

Condensing technology (recovers heat from exhaust gases)

-

Modulating burners (adjust heat output as needed)

-

ECM pumps (variable speed for better efficiency)

Installation Process and Timeline

Understanding the installation process helps set proper expectations:

-

Site Assessment (1-2 hours)

-

Evaluate existing system

-

Determine proper boiler sizing

-

Identify any necessary modifications

-

-

Preparation (4-8 hours)

-

Remove old equipment

-

Install new piping if needed

-

Prepare mounting location

-

-

Boiler Installation (6-12 hours)

-

Mount and connect new boiler

-

Install flue and ventilation

-

Connect to water and gas lines

-

-

System Testing (2-4 hours)

-

Pressure test

-

Check for leaks

-

Verify proper operation

-

Total installation typically takes 2-3 days for a standard replacement, longer for complete system overhauls.

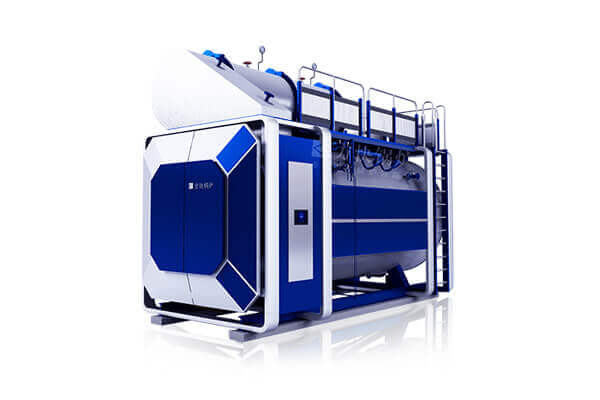

Gas Heating Boiler Parameters

| Types | Thermal Power | Steam Pressure | Rated Steam Temperature | Thermal Efficiency | Fuel | Length * Width * Height | Hot Water Production |

|---|---|---|---|---|---|---|---|

| Unit | Mw | MPa | °C | % | mm | t/h; 10/60°C | |

| T6-700 | 0.7 | -0.02 | 93.5 | 105.50% | Natural gas | 3300 * 1200 * 2100 | 12 |

| T6-1400 | 1.4 | 3900 * 1550 * 2620 | 24 | ||||

| T6-2800 | 2.8 | 4910 * 1830 * 3000 | 48 |

Choosing the Right Installer

Selecting a qualified installer is as important as choosing the right boiler:

What to look for:

-

Proper licensing and insurance

-

Manufacturer certifications

-

Positive customer reviews

-

Detailed written estimates

-

Willingness to provide references

Red flags to avoid:

-

Pressure to make quick decisions

-

Quotes significantly lower than competitors

-

Lack of proper credentials

-

Requests for large upfront payments

Financing Options and Rebates

Several programs can help offset costs:

-

Manufacturer Rebates: $200-$1,000 for high-efficiency models

-

Utility Company Incentives: Up to $500 for energy-efficient upgrades

-

Government Programs: Tax credits for qualifying systems

-

Financing Plans: Low-interest loans through HVAC companies

Maintenance Requirements

Proper maintenance extends system life and maintains efficiency:

Annual Service Should Include:

-

Inspection of heat exchanger

-

Cleaning of burner assembly

-

Testing of safety controls

-

Checking system pressure

-

Flushing if needed

Signs You Need Service:

-

Unusual noises

-

Increased energy bills

-

Uneven heating

-

Frequent cycling

-

Water leaks

Making Your Decision

When evaluating gas boiler heating system prices, consider:

-

Your Budget: Both upfront costs and long-term operating expenses

-

Home Size and Layout: Affects boiler size and type needed

-

Hot Water Needs: Determines whether combi, system, or conventional is best

-

Future Plans: If expanding your home, consider slightly larger capacity

-

Energy Goals: Higher efficiency models save money over time

By carefully weighing these factors and getting multiple quotes from qualified contractors, you can make an informed decision that provides reliable, efficient heating for years to come.

Consultation

Consultation