How Much Does a Biomass Steam Boiler Cost - Biomass Steam Boiler Price

2025-06-13 16:21:37If you're considering switching to renewable energy, a biomass steam boiler could be a smart investment. But how much should you budget for one? Prices typically range from $4,500 to $13,500, depending on size, fuel type, and installation requirements.

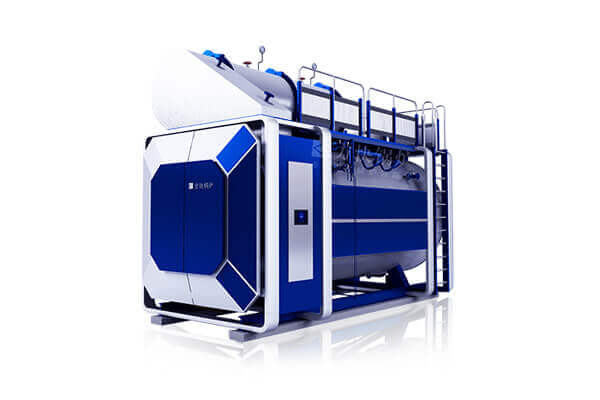

1. Overview of Biomass Steam Boilers

Biomass steam boilers are environmentally friendly equipment that utilizes renewable biomass fuels (such as wood chips, straw, nut shells, etc.) to generate steam. Compared to traditional fossil fuel boilers, they offer significant environmental advantages and sustainability features.

1.1 Basic Working Principle

By combusting biomass fuel to heat water, saturated or superheated steam is produced. The steam can be used for:

-

Industrial processes (food processing, textile dyeing)

-

District heating (schools, hospitals, communities)

-

Power generation systems (cogeneration)

1.2 Main Technical Types

| Type | Fuel Form | Thermal Efficiency | Application Scenarios |

|---|---|---|---|

| Grate-fired | Lump/flake fuel | 75-82% | Small-medium users |

| Fluidized bed | Powdered fuel | 85-90% | Large industrial users |

| Gasification combustion | Multiple forms | 88-93% | High-end environmental projects |

2. In-depth Analysis of Price Factors

The price range for biomass steam boilers typically falls between $4,500-$13,500, depending on the following key factors:

2.1 Capacity Parameters

-

0.5-2 ton/hour: $4,500-$8,000 (small commercial)

-

2-10 ton/hour: $8,000-$15,000 (medium industrial)

-

10-50 ton/hour: $15,000-$50,000 (large industrial)

2.2 Fuel Adaptability

-

Single-fuel type: Lower price but higher operating costs

-

Multi-fuel hybrid: 15-25% more expensive but offers greater fuel flexibility

2.3 Control System Configuration

-

Basic manual control: Starting at $4,500

-

Semi-automatic control: $1,500-$3,000 additional

-

Fully automatic intelligent control: $5,000+ additional

3. Life Cycle Cost Assessment

3.1 Initial Investment Composition

-

Equipment itself: 60-70%

-

Installation engineering: 15-20%

-

Auxiliary systems: 10-15%

-

Other expenses: 5-10%

3.2 Operating Cost Comparison

Example for 10-ton boiler (6,000 operating hours/year):

| Fuel Type | Unit Price | Annual Consumption | Annual Fuel Cost |

|---|---|---|---|

| Natural Gas Boiler | $0.3/m³ | 720,000 m³ | $216,000 |

| Diesel Boiler | $0.8/L | 540,000 L | $432,000 |

| Wood Pellets Boiler | $120/ton | 900 tons | $108,000 |

3.3 Maintenance Costs

-

Annual routine maintenance: $800-$1,500

-

Major overhaul every 3 years: $3,000-$5,000

-

Wear parts replacement: $200-$500/year

4. Purchasing Recommendations and Considerations

4.1 Key Supplier Selection Points

-

Certifications: Check for international certifications like ASME, CE

-

Project References: Request case studies of similar projects

-

After-sales Service: Confirm maintenance response times

4.2 Installation Considerations

-

Fuel storage space reservation (recommended 3-month supply)

-

Dust removal system requirements

-

Compliance with local emission standards

5. Market Development Trends

-

Intelligent Upgrades: Popularization of IoT remote monitoring systems

-

Ultra-low Emission Technology: New generation products with NOx<50mg/m³

-

Modular Design: Facilitates capacity expansion and relocation

6. Frequently Asked Questions

Q: How to improve thermal efficiency of biomass boilers?

A: Recommended measures:

-

Install flue gas heat recovery devices (5-8% improvement)

-

Optimize combustion control systems (3-5% improvement)

-

Regular heat exchange surface cleaning (maintains design efficiency)

Q: How to calculate payback period?

A: Typical calculation formula:

(Total investment - subsidies) ÷ (Annual fuel savings + emission reduction benefits) = Payback period

Generally 3-5 years for industrial projects

For personalized solution recommendations, please contact our technical team: +86 15690850708, offering free consultation and design services.

Consultation

Consultation