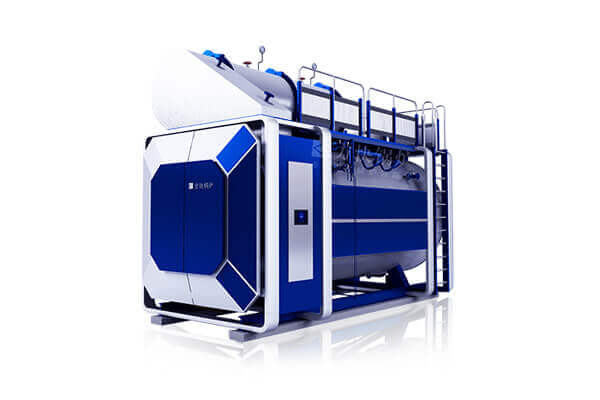

Heating gas boiler parts

2022-04-27 14:01:27

Heating gas hot water boilers are indispensable heating equipment in many cities in winter. The high-temperature hot water heated by the boilers is continuously and stably delivered to every household through pipes. For gas boilers dedicated to heating, they must be matched by auxiliary equipment to be used normally.

According to the different division of labor in the system, there are the following types of gas boiler auxiliary machines.

1. Dissolved water supply system: including soft water, demineralized water system, deaerator, water supply pump, water tank, ammonia adding device, dosing device, etc.

2. Steam (hot water) system: This system of the gas boiler mainly includes a steam (water) cylinder and a temperature reducer.

3. Fuel supply and combustion system: This system is an important system of gas boiler auxiliary equipment, mainly including gas decompression station, oil tank, fuel valve group and burner, etc.

4. Smoke and air system: blower, induced draft fan, chimney, etc.

5. Sewage (steam) system: continuous row, fixed row, sampler, muffler.

6. Electronic control system: common control, PLC control, DCS control.

7. Other equipment in the boiler room: heat exchange station, circulating pump, decontamination device, etc.

According to the different functions of auxiliary accessories, they can be divided into the following types:

1. Safety accessories: The safety accessories of natural gas boiler auxiliary equipment mainly include safety valves, explosion-proof doors, water seal safety devices, high and low water level control alarms, etc.

2. Safety instruments: The safety instruments in the auxiliary equipment of natural gas boilers include flow meters, pressure gauges, temperature gauges, travel control instruments, water level gauges and protection devices.

3. Drum: The natural gas drum is a closed part of the heating surface. It connects the heating surfaces together and forms a water circulation loop with the water cooling wall and the descending pipe. The steam and water are stored in the drum, which can adapt to load changes. Separation device, etc. to ensure the quality of soda.

4. Furnace: The furnace is used to ensure that the fuel of the natural gas boiler is burned out and the temperature of the outlet flue gas is cooled to a value where the convection heating surface can work safely.

5. Air preheater: The air preheater in the auxiliary machine of the natural gas boiler is used to heat the air to strengthen the ignition and combustion, absorb the waste heat of the flue gas, and reduce the exhaust gas temperature. It is an important auxiliary machine to improve the operation efficiency of the heating gas boiler. one.

According to the different division of labor in the system, there are the following types of gas boiler auxiliary machines.

1. Dissolved water supply system: including soft water, demineralized water system, deaerator, water supply pump, water tank, ammonia adding device, dosing device, etc.

2. Steam (hot water) system: This system of the gas boiler mainly includes a steam (water) cylinder and a temperature reducer.

3. Fuel supply and combustion system: This system is an important system of gas boiler auxiliary equipment, mainly including gas decompression station, oil tank, fuel valve group and burner, etc.

4. Smoke and air system: blower, induced draft fan, chimney, etc.

5. Sewage (steam) system: continuous row, fixed row, sampler, muffler.

6. Electronic control system: common control, PLC control, DCS control.

7. Other equipment in the boiler room: heat exchange station, circulating pump, decontamination device, etc.

According to the different functions of auxiliary accessories, they can be divided into the following types:

1. Safety accessories: The safety accessories of natural gas boiler auxiliary equipment mainly include safety valves, explosion-proof doors, water seal safety devices, high and low water level control alarms, etc.

2. Safety instruments: The safety instruments in the auxiliary equipment of natural gas boilers include flow meters, pressure gauges, temperature gauges, travel control instruments, water level gauges and protection devices.

3. Drum: The natural gas drum is a closed part of the heating surface. It connects the heating surfaces together and forms a water circulation loop with the water cooling wall and the descending pipe. The steam and water are stored in the drum, which can adapt to load changes. Separation device, etc. to ensure the quality of soda.

4. Furnace: The furnace is used to ensure that the fuel of the natural gas boiler is burned out and the temperature of the outlet flue gas is cooled to a value where the convection heating surface can work safely.

5. Air preheater: The air preheater in the auxiliary machine of the natural gas boiler is used to heat the air to strengthen the ignition and combustion, absorb the waste heat of the flue gas, and reduce the exhaust gas temperature. It is an important auxiliary machine to improve the operation efficiency of the heating gas boiler. one.

Consultation

Consultation